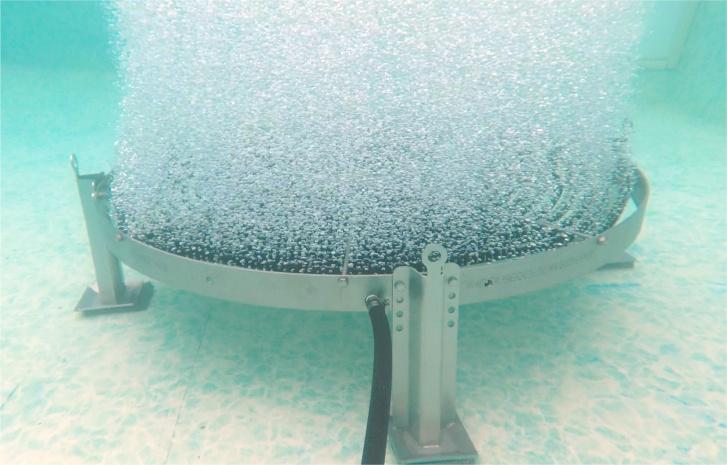

L’OctoAir est un diffuseur de grade industriel fabriqué au Canada pour l’aération, l’oxygénation et le déglaçage. Étant résistant à la corrosion, à la détérioration due au pH, à la température, à la salinité de l’eau ainsi qu’à un large éventail de produits chimique, il est conçu pour les industries et les municipalités. Celui-ci, composé d’un support en acier, permet de fixer efficacement le Tuyau Bulle® en spirale à l’aide d’une fixation intégrée. Il existe en deux différents formats soit l’OctoAir-10 et l’OctoAir-60, tous deux facilement manœuvrables et extrêmement efficace.Les équipes d’installation nous confirment que le diffuseur OctoAir est facile à installer, entretenir et par-dessus tout bien conçu.

Vidéo de déglaçage avec diffuseur Octoair

Vidéo d'aération avec diffuseur Octoair

Spécifications – Comparez nos deux modèles d’OctoAir

| OCTOAIR-10 | OCTOAIR-60 | ||

|---|---|---|---|

| SPÉCIFICATIONS | Applications | - Aération - Déglaçage - Mélange - Réduction de pathogènes |

- Aération - Déglaçage - Mélange - Réduction de pathogènes |

| Diffuseur | - Support en acier inoxydable 304 - 4 pattes ajustables* - 100 pi. (30 m) de Tuyau Bulle® 1/2'' non lesté - Valve anti-retour NON INCLU: - Tuyau d'amenée d'air Torpedo - Compresseur |

- Support en acier inoxydable 304 - 4 pattes ajustables* - 300 pi. (90 m) de Tuyau Bulle® 3/4'' non lesté - Valve anti-retour - Instructions d'assemblage NON INCLU: - Tuyau d'amenée d'air Torpedo - Compresseur |

|

| Livraison | Assemblé | Non assemblé | |

| Garantie | 1 an | 1 an | |

| Options | Bouée de marquage Anodes pour eau salée et/ou saumâtre |

Bouée de marquage Anodes pour eau salée et/ou saumâtre |

|

| DIMENSIONS | Diamètre | 48'' (122 cm) | 96'' (244 cm) |

| Poids | 65 lb (29,4 kg)** | 315 lb (143 kg) | |

| Assemblage | Pattes seulement | Requis | |

| PRESSION | Maximale | 50 PSI (3,4 BAR) | 70 PSI (4,8 BAR) |

| Minimale | 20 PSI (1,4 BAR) | 20 PSI (1,4 BAR) |

(*) Les pattes ajustables surélevées gardent le tuyau au-dessus du fond du bassin; pattes fait sur mesure au besoin.

(**) Plusieurs OctoAir-10™ peuvent être empilés l’un sur l’autre pour faciliter le transport sur palettes.

(***) L'unité fabriquée en SS316 est aussi disponible sur demande

Fiche Technique Octoair (PDF)

OctoAir-60 a été dessiné et conçu expressément pour l’aération et le déglaçage industriel pour des projets de grandes envergures. Avec un débit d’air requis jusqu’à 75 CFM, les 300 pieds de Tuyau-Bulle® ¾ » contenus dans la structure de l’OctoAir-60 permettent de plus grandes performances de transfert d’oxygène. Également, la conception du diffuseur permet de nourrir en air le Tuyau Bulle® ¾ » par les deux extrémités. Les applications qui nécessitent un diffuseur de calibre industriel résistant à la corrosion, facilement manœuvrable, extrêmement efficace seront bien servit avec l’OctoAir-60.

L’air comprimé est poussé le long du tuyau d’alimentation d’air jusqu’au diffuseur OctoAir. Les micros-bulles sont relâchées par les micros perforations tout au long du Tuyau Bulle®. Le relâchement constant et dense de fines bulles (une caractéristique du Tuyau Bulle® intégré dans le design de l’OctoAir libère un haut niveau d’oxygène, tout en créant un mouvement ascendant important qui transporte l’eau plus chaude et plus dense du fond vers la face inférieure de la couche de glace à la surface. L’OctoAir modifie également la densité de l’eau chaude en y introduisant de l’air. Cette réduction de la densité de l’eau, avec la sortie régulière des bulles, produit une circulation optimale de l’eau chaude et donc la fonte des glaces.

Dans les situations où l’OctoAir est déjà en place, il fournit une prévention fiable et efficace de l’accumulation de glace, même dans les températures les plus froides.

Aucune pièce mécanique ou électrique n’est en contact avec l’eau, ce qui signifie des coûts d’opération réduits.

Vérifier avec les autorités pour vous assurer que l’ajout de déglaceurs est autorisé dans votre municipalité. L’espace déglacée devrait être bien délimité avec une pancarte pour aviser toutes personnes du danger durant l’hiver. À utiliser avec tous types de systèmes de dégivreur / déglaceur.

Sécurité

Vérifiez avec les autorités locales pour vous assurer que l'ajout de déglaçeurs est autorisé dans votre municipalité. L'espace déglacée devrait être bien délimité à l'aide d'une pancarte pour aviser toute personne du danger. À utiliser avec tous types de système de déglaçage. Cliquez ici pour faire l'achat d'une pancarte "Glace mince".

Une étude de cas a pour but d'examiner une instance ou une situation spécifique dans son contexte naturel. En analysant des cas réels, les chercheurs peuvent affiner ou remettre en question les cadres théoriques établis.

Case Study : Déglacage dans une mine pour augmenter la capacité de stockage d’un bassin de rétention.