- Prix normal

- $249.00 CAD

- Prix réduit

- Prix normal

-

- $249.00 CAD

- Prix unitaire

- par

Frais d’expédition calculés à l’étape de paiement

Les diffuseurs à fines bulles, tels que notre Tuyau Bulle®, produisent de nombreuses et très petites bulles d’air. Elles sont inférieures à 1 mm à la sortie du diffuseur. Ces fines bulles montent lentement du fond d’un bassin d’une usine de traitement des eaux usées ou du fond d’un étang ou d’un lac. Elles assurent un transfert substantiel et efficace de l’oxygène dans l’eau. Cet oxygène, combiné aux nutriments présents dans les eaux usées et les sédiments, permet aux bactéries de produire des enzymes. Ces enzymes favorisent la décomposition des déchets et sédiment composés de la matière organique accumulée.

Formats Disponibles (Diamètre intérieur)

- 15 mm ( ½”) : Ensemble standard disponible à l'achat en ligne.

- 20 mm ( ¾”) : Contactez nous pour une soumission.

- 25 mm (1”) : Contactez nous pour une soumission.

- 30 mm ( 1 ¼”) : Contactez nous pour une soumission.

- Le Tuyau Bulle® est flexible. Il a une excellente mémoire de forme et une bonne résistance à la torsion.

- Sans danger pour l’environnement (ne contient pas de plomb).

- Fait au Canada selon nos spécifications. Garantie de 1 an.

- Taux de transfert d’oxygène élevé. Évaluation complète des capacités de transfert d’oxygène effectuée par une firme indépendante. Disponible sur demande.

- Applications à large spectre. De l’étang agricole jusqu’aux plus grands projets industriels.

- Conçu pour les applications en eau douce ou salée. En eau peu profonde ou profonde.

- La pression prévenant le colmatage, le tuyau requiert un entretien minime.

- Aucune pièce mécanique en mouvement ou électrique dans l’eau.

- PVC hautement résistant aux produits chimiques, à la salinité et aux écarts de température.

- Tuyau disponible en format lesté ou non lesté.

- Le tuyau est vendu avec tous les éléments de quincaillerie requis, prêt pour l’installation.

Vidéo sur le Tuyau Bulle®

Le Tuyau Bulle® peut être un composant de :

- Systèmes d’aération CanadianAir

- Système Mini-Air

- Systèmes de déglaçage Thawline

- Diffuseur industriel OctoAir pour l’aération et le déglaçage (intégré à la base en acier inoxydable)

- Diffuseur pour remonter l'eau en aquaculture SalmoAir®

Fabriqué en PVC très résistant mais flexible, le Tuyau Bulle® conserve sa forme et résiste bien à la torsion. En entrant dans le tuyau, l’air comprimé crée une pression interne. Les perforations précises, des deux côtés de la totalité de la longueur du tuyau, permettent à l’air comprimé d’être libéré. Ceci crée de fines micro-bulles tout en prévenant l’encrassement, problème typique des diffuseurs poreux. L’air ainsi libéré forme un rideau de bulles uniforme qui optimise le transfert d’oxygène. Il facilite également la bonne circulation de l’eau tout au long de la colonne d’eau. L’utilisation du Tuyau Bulle® réduit au minimum la perte de charge du système et ne requiert aucune électricité sous l’eau. Le Tuyau Bulle® offre une performance d’aération globale supérieure aux autres dispositifs d’aération. Le Tuyau Bulle® contribue à réduire substantiellement les coûts d’installation, d’entretien et de consommation énergétique.

Pour le déglaçage, les bulles qui sortent du Tuyau Bulle® entrainent l’eau dense, lourde et plus chaude des profondeurs vers la surface. Ce mouvement de l’eau plus chaude vers la surface inhibe la formation de glace.

Noter que le Tuyau Bulle® flottera en eau salé.

Inclus dans la boîte (Pour les kits vendus en ligne seulement.)

- 1x Diffuseur Tuyau Bulle®

- 1x valve antiretour

- 2x Collets

- Instructions

Résultats des tests sur la capacité de transfert d’oxygène

Certification du Tuyau Bulle®, diffuseur à fines bulles En 2011, nous avons fait tester la capacité de transfert d’oxygène du Tuyau Bulle® par une firme indépendante, GSEE Inc. de Laverne TN. Les tests ont été réalisés sur le Tuyau Bulle® ½″ et ¾″ et le diffuseur industriel OctoAir-10. À l’été 2017 nous avons donné un autre mandat à GSEE Inc. pour tester le Tuyau Bulle® à des débits d’air et profondeurs plus élevées et avons aussi réalisés les test sur notre Tuyau Bulle® 1″ et diffuseur OctoAir-60.

“En général, les résultats obtenus pour les systèmes d’aération que l’on retrouve chez Produits Etang.ca sont excellents et ont produit parmi les plus hautes valeurs mesurées en SOTE que GSEE, Inc. ait jamais mesuré.’’(*)

GSEE, Inc. Environmental Consultants, LaVergne, TN, Sept. 2011.

(*) Traduit de l’anglais

Formats disponibles

- Dimensions disponibles (D.I.): 15 mm ( ½″), 20 mm ( ¾″), 25 mm (1″) et 30 mm ( 1 ¼″)

- Disponible lesté ou non lesté pour les formats de 15 mm ( ½″) et 20 mm ( ¾″)

- Les formats de 20 mm ( ¾″), 25 mm (1″) et 30 mm ( 1 ¼″) ont un câble en acier intégré au ballast pour offrir une meilleure résistance et pour le poids.

- Longueur disponibles: en rouleau, en bobine ou en coupe sur mesure, contactez-nous pour plus de détails.

Nos produits avec Tuyau Bulle®

Le Tuyau Bulle® est disponible au pied ou en rouleaux et dans une variété de formats. Contactez-nous pour connaître les prix et les détails.

Fiche Technique (PDF)

Le Tuyau Bulle® est un diffuseur linéaire qui comporte deux rangées opposées de trous fins sur toute la longueur du tuyau. La pression exercée par l’air en provenance du compresseur ouvre les trous et permet la libération de fines microbulles dans l’eau. Cette conception particulière réduit les risques de colmatage par le biofilm ou une baisse d’efficacité au fil du temps comparativement aux autres technologies de diffuseur à fines bulles.

Le Tuyau Bulle® a une excellente efficacité standard de transfert d’oxygène de la phase gazeuse à la phase dissoute (SOTE) et une grande efficacité d’aération standard (SAE).

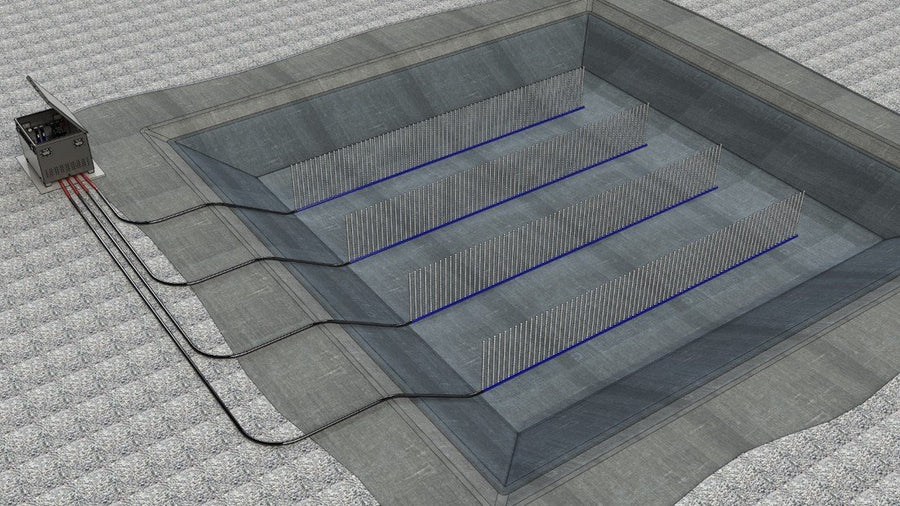

Peut importe l’envergure de vos opérations, le principe demeure le même : un compresseur est connecté au Tuyau Bulle® par l’entremise d’une ligne d’amenée d’air munie d’un clapet antiretour. Étang.ca vous propose toutes les pièces nécessaires pour la mise en place d’un système d’aération efficace et fiable. Nous pouvons vous conseiller sur la force du compresseur et la disposition du tuyau. Nous pouvons vous suggérer des modifications pour rentabiliser vos systèmes déjà en place et diagnostiquer les anomalies de fonctionnement. Notre expérience dans la conception de systèmes d’aération ou de déglaçage avec le Tuyau Bulle® est éprouvée et efficace.

Le Tuyau Bulle® nécessite un compresseur, vous pouvez choisir entre un compresseur à diaphragme et à piston. (Voir les compresseurs ici.) Le compresseur doit être installé dans un cabinet. Ce cabinet doit offrir une bonne circulation d'air pour éviter la surchauffe et le protéger des mauvaises températures. (Voir plus sur les cabinets ici.) Si le compresseur n'est pas installé dans un cabinet, il est important que celui-ci soit protégé dans un abris ventilé. Quand l'abris est choisit, assurez vous de monter le compresseur sur une base et de le sécuriser avec des vis au mur, au sol ou sur une étagère. Sécuriser la base empêche le compresseur de bouger quand il est en marche. Il n'est pas recommandé d'utiliser une extension, assurez vous qu'une prise électrique soit à la porté des fils du compresseur. (1,8m/6 feet)

Schéma d'un diffuseur avec le Tuyau Bulle®;

Avant de connecter le Tuyau Bulle®, déroulez le afin de vous assurer qu'il n'est pas tordus. Un tuyau bien tendu permet une diffusion d'air uniforme à travers toute sa longueur. Vous pouvez laisser le tuyau déroulé avant son installation pour que celui-ci prenne la forme.

Le Tuyau Bulle® est également compatible avec le tuyau Torpedo. (Voir plus sur le torpedo ici.) Si demandé à l'avance, le Tuyau Bulle® peut être connecté au clapet (check valve) avant la livraison. (Des coûts d'assemblage peuvent toutefois s'appliquer.)

Si installé dans un étang large, l'installation du Tuyau Bulle® peut être fait par bateau. Le compresseur doit être démarré, le tuyau déroulé sur la berge et le reste du tuyau roulé, dans le bateau. Tout en gardant le tuyau Torpedo en main, allez sur l'eau et déroulez le jusqu'à atteindre la zone désiré pour le diffuseur Tuyau Bulle®. Avec le tuyau diffuseur déjà connecté au tuyau Torpedo, déroulez lentement dans l'eau le tuyau pendant qu'il coule au fond de l'eau. Avec le compresseur en marche, vous devriez voir apparaître des bulles et vous pourrez les utiliser comme aide visuel afin de vous assurer que le tuyau diffuse correctement sur toute sa longueur.

Si installé dans un petit étang, il est également possible de procéder à l'installation sans bateau. (Il est même recommandé de procédé ainsi.) Démarrez le compresseur juste avant l'installation du tuyau dans l'eau. Les bulles vous guideront pour le positionnement dans l'eau. Utilisez une longue corde (longueur double de l'étang) et une petite corde (environ 1 ou 2 pied). Fromez une boucle à la fin du diffuseur utilisant la petite corde (boucle ci-bas). Passez la plus longue corde à travers la boucle et en tenant les deux bouts de la longue corde, utilisez la pour tirer le diffuseur en place dans l'eau. Le tuyau diffuseur coulera à l'endroit désiré, au fond de l'eau. Une seconde personne devrait rester en place avec le début du tuyau pour aider à son bon positionnement. Une fois bien positionné, relâchez un bout de la longue corde et tirer l'autre pour récupérer la corde.

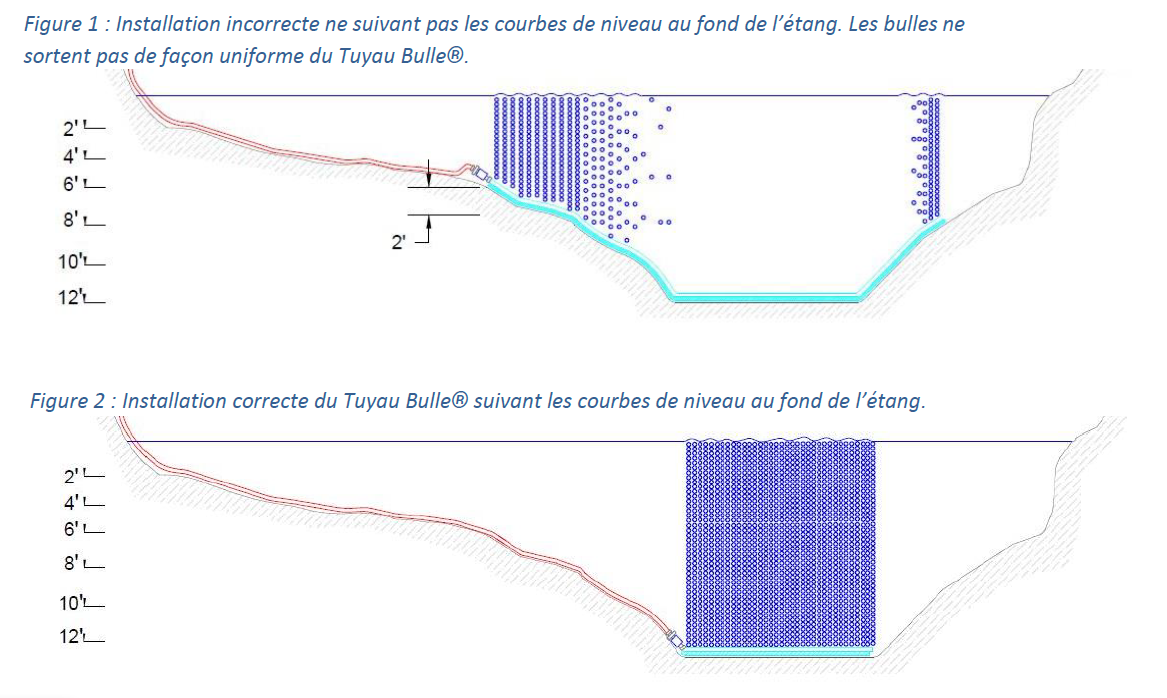

Ne sous-estimez pas le positionnement du Tuyau Bulle®, l'air est paresseux, il cherchera la sortie d'air la plus proche. Placez le Tuyau Bulle® en le maintenantaussi horizontal que possible (maximum 1 pied de dénivelé). Le tuyau peut être disposé en cercle, en courbeou en ligne droite pour suivre une bathymétrie continue. Si vous ne connaissez pas la profondeur de votre étang, nous recommandons d'utiliser un outil traqueur de profondeur.

Si vous installez l'unité dans un point d'eau qui est extrêmement stratifié, soyez prudent au démarrage. Nous vous conseillons de démarrer l'aération de votre étang de manière progressive, soit par une heure d'aération par jour et ce dans la lumière du jour. Après la première semaine, vous pourrez augmenter graduellement le temps d'aération jusqu'à ce que le système fonctionne sans-cesse. Les jours ensoleillés sont préférables aux jours nuageux puisque la photosynthèse fournit de l'oxygène pendant que l'eau circule et se mélange. Pour plus d'information sur un démarrage progressif, cliquez ici.

Notre Tuyau Bulle® a été utilisé depuis plus de 15 ans pour un large éventail d’applications dans diverses industries, dans le secteur gouvernement et municipal et le secteur privé. Le Tuyau Bulle® est en utilisation à tous les paliers du gouvernement (fédéral, provincial et municipal), dans les usines de fabrication et de transformation de la matière, dans le secteur de l’exploitation minière, auprès des autorités portuaires, en aquaculture , en agriculture, dans les parcs et les sites récréatifs, auprès des firmes d’ingénierie, pour l’aménagement paysager et la remise en valeur des terrains, en construction maritime, auprès des universités et des centres de recherche et auprès des propriétaires de lacs et étangs privés pour n’en nommer que quelques-uns. Le Tuyau Bulle® se retrouve maintenant sur tous les continents de la planète.

Les applications d’aération, de déglaçage et de rideaux de bulles d’air incluent, mais ne sont pas limitées, les suivantes:Rideaux de bulles en aquaculture

- Pour l’aération de divers plans d’eau tels que les lagunes d’aération des eaux usées, les usines de traitement des eaux usées, les bassins de lixiviat, les étangs naturels, les étangs d’irrigation, les lacs, les bassins d’aquaculture, les bassins de rétention des eaux pluviales, les fosses septiques, les canaux, etc.

- Pour le déglaçage de quais, des prises d’eau des centrales électriques, du littoral et des marinas, des structures navales et portuaires, de l’amarrage des navires industriels, des couloirs de transport maritime, des opérations de pompage et des systèmes de refroidissement des centrales nucléaires.

- Pour une circulation efficace, du bas vers le haut, dans la colonne d’eau et le mélange de l’eau à des fins de traitements, déglaçage ou toute autre application.

- Pour la réduction des agents pathogènes (les bulles entraînent vers la surface les eaux des profondeurs et l’expose aux rayons UV qui détruisent certains agents pathogènes).

- Pour l’atténuation des nuisances sonores sous-marines par l’entremise de barrières diphasiques (rideaux de bulles). Pour assurer la protection de l’environnement marin des ondes de choc sous-marines lors de travaux sous-marins (explosion de munitions, travaux de battage, de forage, ou de déroctage, opérations de recherche pétrolière à effet sismique, etc.).

- Pour créer une barrière physique permettant de contrôler le mouvement de la vie marine et les débris flottants. Les rideaux de bulles peuvent empêcher ou réduire le passage des méduses, poissons, herbes aquatiques invasives, débris, sédiments, etc.

- Pour une amélioration de la qualité de l’eau, y compris sa clarté et la réduction de la présence d’algues, du sulfure d’hydrogène (H2S) et des mauvaises odeurs.